Battery Locomotives and Energy Storage Systems

RPS Energy Storage System

Based on the success of light duty Hybrid and Battery Electric Vehicles (EVs) such as the Prius for commuter applications; it was evident to the RPS founders, that the technology, products and infrastructure evolving to foster the growth of EVs would be scalable and viable for industrial and rail applications.

RPS was awarded a grant in 2014 to demonstrate portions of the technologies scaled up for these applications. The result of this grant and several subsequent grants was the development of the RPS approach for packaging, managing and cooling hardened, safety interlocked, battery based, energy storage systems and related power electronics necessary to provide onsite and onboard electrical power for locomotive and industrial applications.

The resulting product solution is a modular, serviceable, self-contained battery energy system that can be configured and manufactured to support applications with capacity requirements from three hundred kilowatt-hour (300 kWh) up to three megawatt-hour (3 MWh) of storage. This is an ideal range as it fills an available gap in the energy storage market between small scale systems, such as on road electric vehicles and consumer solar buffer storage, and large scale systems for heavy industry and grid level buffer storage.

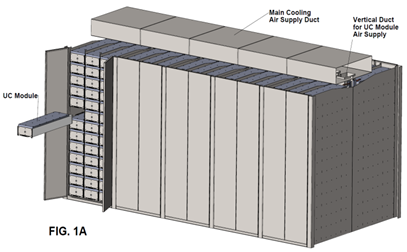

The RPS Series/Parallel configuration architecture consists of a storage rack containing removable, replaceable battery modules or “cans”. The Rack provides structure, connectivity, cooling and power distribution to and from the cans which each contain local cooling distribution, communication and battery management at the battery component level.

This architecture allows RPS battery systems to be easily managed, maintained and serviced in the field. Each can is both electrically and thermally isolated such that, in the event of a battery component failure within it, a “can” will self-isolate thus slightly lowering the storage capacity of the system without functional impact to the user. The “can” then communicates the fault to the system such that the user is notified to replace the faulted “can” at the next scheduled maintenance interval.

Locomotive Battery Electric Conversions

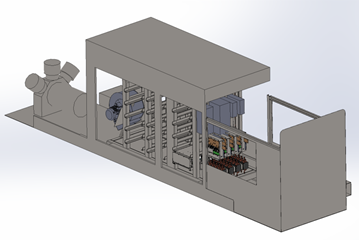

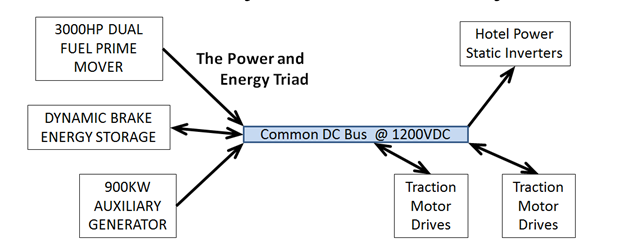

The RPS battery energy system conversions provide a transition to on-board electrified and hybrid rail operation for both commuter passenger and switcher locomotive operators. For passenger and switcher locomotives, the battery system upgrade replaces the diesel engine and generator with a battery system and power electronics. These systems incorporate the patented RPS Energy Storage System and interface it with the existing locomotive electronics and electrical power circuits such as not to alter the function, operation, control or safety systems.

The conversion packages can utilize existing mounting interfaces to simplify installation and includes all the necessary auxiliary motors and systems for traction motor cooling, air compressor drive and power electronics management. The system also includes the necessary charging system interface as well as provisions for incorporating wireless power transfer for hands free ‘opportunity charging’ while the locomotive through or temporarily idle at common rail points.

RPS has two parallel battery locomotive programs, one based on lead-carbon batteries in a R&D locomotive inherited from a Class 1 railroad, and a second program based on repurposed ‘2nd life’ lithium ion batteries from light duty electric vehicles.

RPS is also developing electric zero emission motive power based on batteries, electronics and safety systems developed from the automotive industry. Initially this will take the form of switching locomotives for passenger and freight yard use. A prototype is under construction at the company’s yard in Orange County. Within the next six months work will begin on a mainline passenger locomotive.

Zero Emissions Booster Locomotive

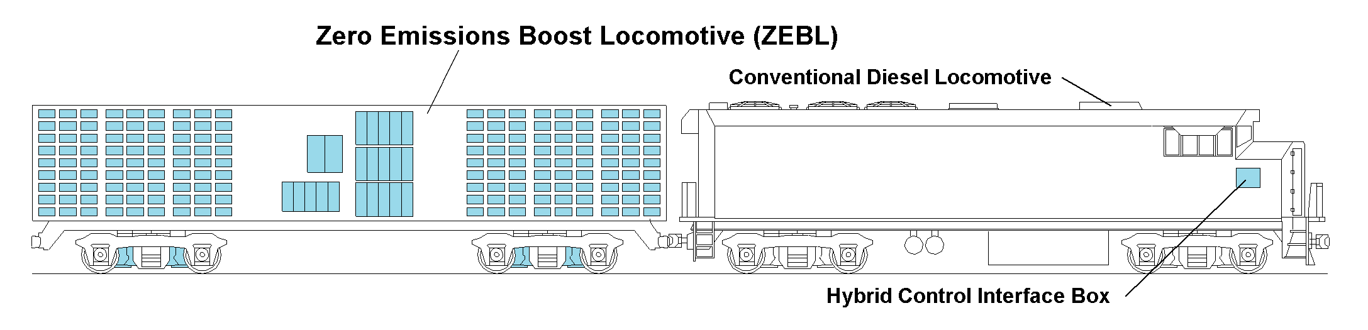

The Zero Emissions Booster Locomotive (ZEBL) is a self-contained all-electric booster locomotive designed to increase performance and reduce emissions of existing commuter trains.

By replacing the diesel engine and generator with battery system and power electronics, a diesel passenger locomotive is converted into a ZEBL. A hybrid train is created when a ZEBL is added as a second locomotive to a passenger train that already includes a diesel locomotive. This hybrid system increases acceleration and allows longer trains, reduces diesel fuel consumption, lowers emissions and creates redundant power systems to prevent train stoppages due to mechanical failures.

This ZEBL can work in conjunction with a BATS fitted diesel as a hybrid unit, further reducing emissions and fuel consumption, and improving performance for regional passenger trains.

- Reduces fuel consumption and brake wear

- Doubles acceleration and capability of the consist to which it is added

- Provides Plug n Play capability with no changes to infrastructure or operations

- Built on conventional locomotive frame and trucks

- Integrates Crash Energy Management (Optional Pushback Couplers)

- Provides much of the benefit of electrification without infrastructure investment

- Can be implemented on shared lines without compromising rail usage

- Provides path to Hydrogen or Natural Gas fueled ‘near-zero’ emission hybrid pair